|

Maximum Bend Length |

47 in. |

|

Minimum Qualifying Part Size |

0.05 in x 0.05 in (12.7mm x 12.7mm) for formed parts |

|

Maximum Pressing Force |

80 tons |

|

Bend Angles |

1 degree ‘kick’ to 135 degrees |

|

Bending Output |

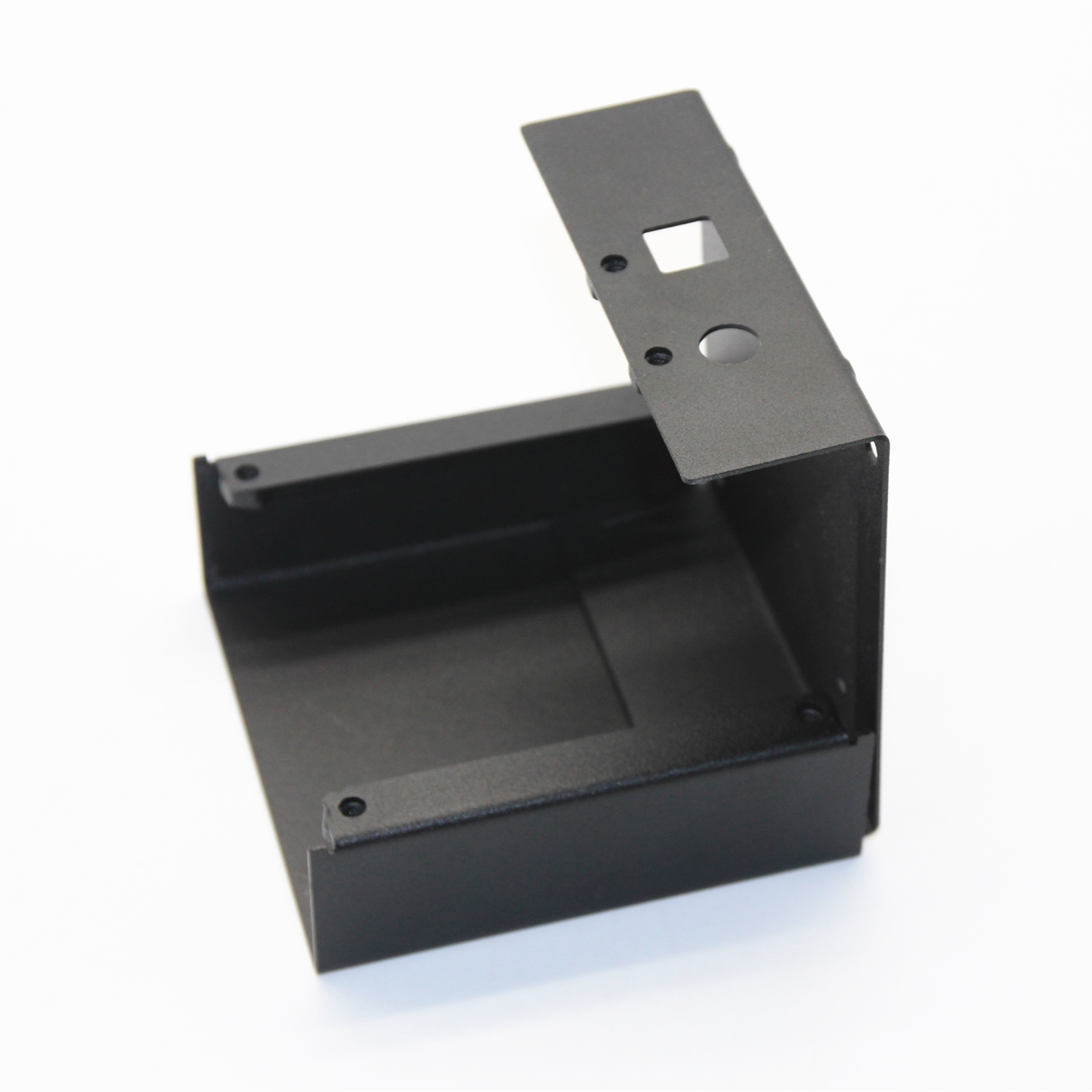

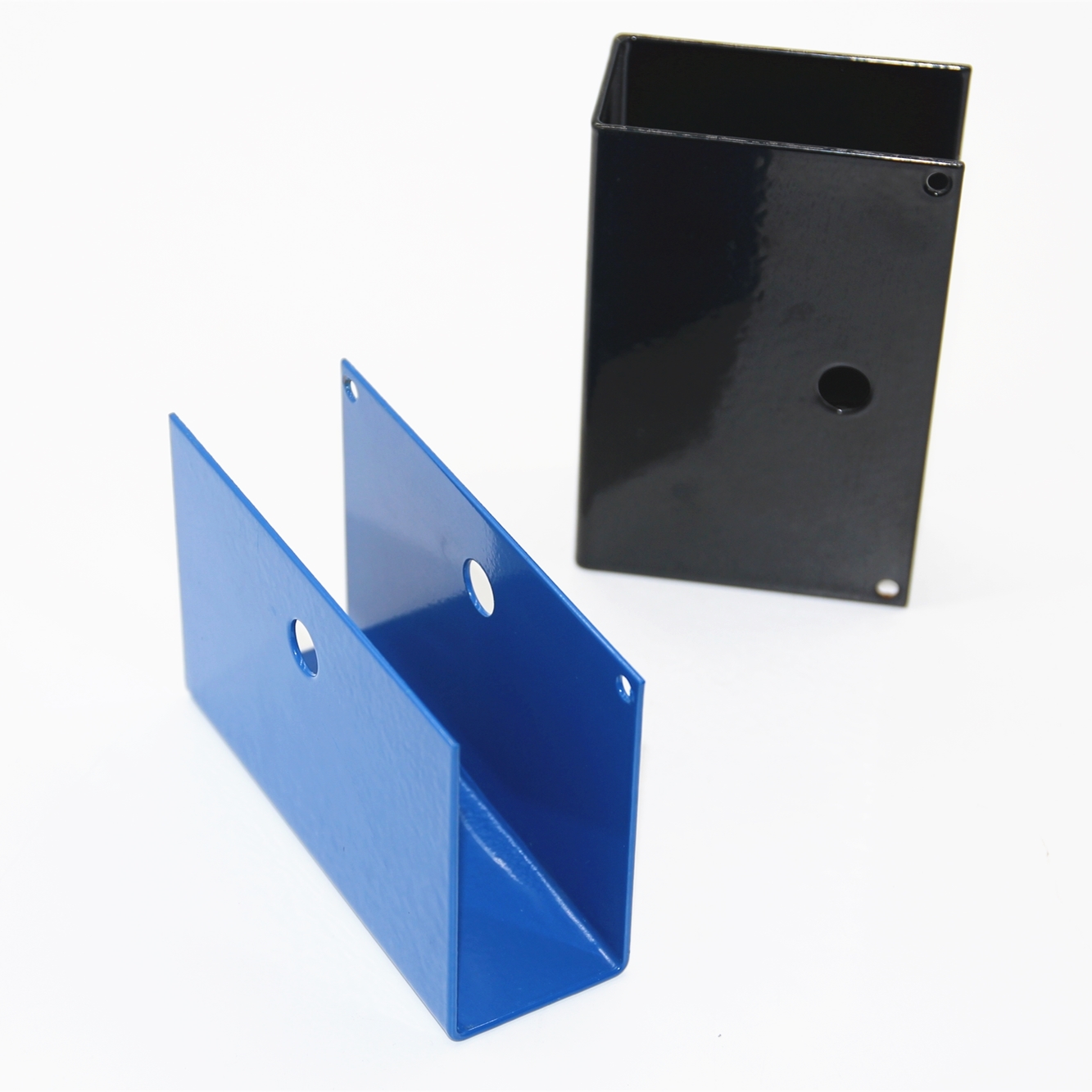

Linear bends—external and internal flanges |

|

Maximum U-Channel Ratio |

2:1 (width:height) |

|

Internal Radius Tooling Options |

0.01 in. to 1 in. (standard tooling increments) >1 in. radius bends will be bump formed

|

|

Offsets |

Standard offset tooling sizes |

|

Hems |

Closed hems up to 47 in., open hems up to 36 in. |

|

Best way to cooperate |

Provide detailed CAD drawings or detailed operating parameters contact us for the shortest machining cycle time and a quote to ensure the description of the bend is consistent with the operating details |

|

Material |

Grade |

Thicknesses Available |

|

铝质 |

|

|

|

钢 |

|

|

|

不锈钢 |

|

|

|

铜 |

|

|

|

黄铜 |

|

|

Obtain An Instant Quote by uploading a 3D CAD file (including STEP, STP, SLDPRT, DXF, IPT, PRT, or SAT formats) through our Instant Quoting Engine.

Crack: Select the appropriate bending radius and reduce the bending speed.

Deformation: Consider the elasticity and plasticity of the material in the design, and choose the bending order reasonably.

Asymmetric bending: to ensure that the fixture uniform force, avoid local excessive pressure.

During the bending process, the material undergoes elastic and plastic deformation. Elastic recovery is estimated by calculating “bending compensation” to ensure that the final Angle meets the design requirements. It is generally necessary to add 1-2° to the bending Angle as compensation.

Stainless steel: The commonly used stainless steel has 304, 316 and 430 and other grades.

Alloy steels such as A36, 1018 and 4140 are popular in metal bending due to their high tensile strength, durability, cost-effectiveness and versatility.

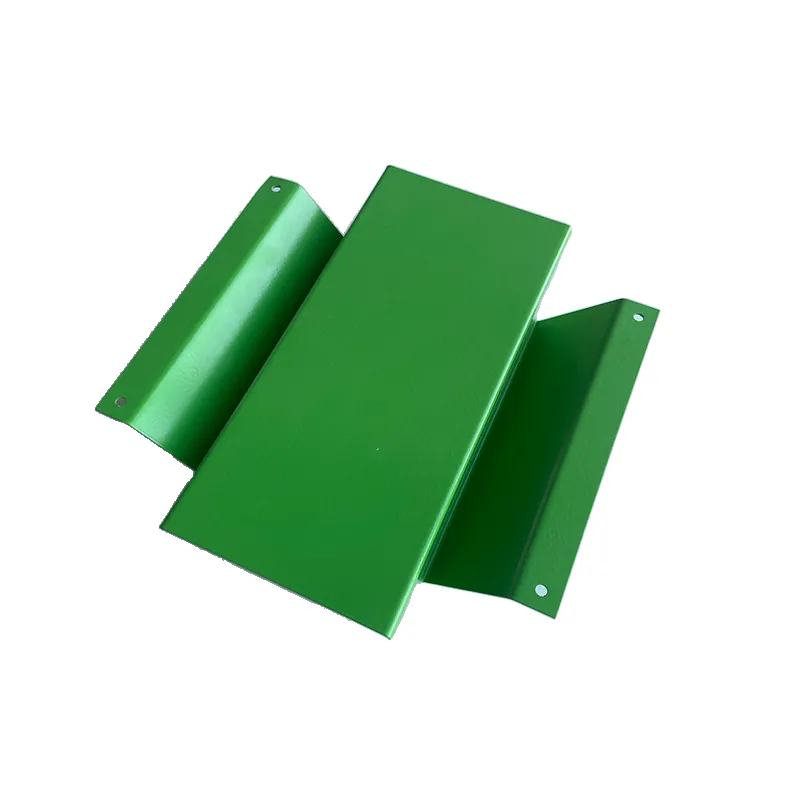

Aluminum material: Aluminum is malleable and easy to form different shapes and curvatures. It has excellent corrosion resistance and strength-to-weight ratio.

Copper: Copper is a soft material and the sheet is easily bent. However, careful handling and control of force is required to avoid surface damage or cracking.

The main advantage of bending is its ability to create complex parts without any seams. In addition, it is precise, cost-effective and versatile. It is capable of manufacturing rugged components for a variety of industries.